So it’s dark and wet so that’s when I think about doing my yearly lambic beer that I leave out in the garden and let it inoculate with wild yeast and bacteria under my now dormant grape vine. It uses a turbid mash regime and the the general idea is it uses up to 40% raw wheat and then the rest is a simple base malt. At various points wort is pulled from the mash and then boiled so there is lots of starch. Only certain wild bacteria can ferment the starch over a long long time so you get a sour and unique tasting beer due to the bacteria and yeast that fall into it due to your location, environmental conditions and yearly variances.

As its a rare brew I generally have a little read up on it to refresh my memory and I once again came across a simpler turbid mash intended for lower alcohol siaisons posted by the very excellent Hors Catégorie Brewing. This was talking about George Maw Johnson who was the first editor of the belgian brewers magazine Le Petit Journal du Brasseur even though he was from Kent in not Belgium.

So the simpler turbid mash uses the same idea of big brother but it only has one rather than two turbid pulls. The intended use of this is very different though. The cloudy starch filled wort is meant to be fermented with only a traditional yeast rather than with the addition of souring bacteria. This means that there is some sweetness left to taste after the yeast has completed as there is unfermented starch left in the beer. The beer will also have more mouth feel than a modern saison which are crystal clear.

As I like fruit beer and siasons it gave a chance to combine the two but also tweak the recipe and keep a little sweetness in the beer to give the fruit flavour a lift. Modern siasons are bone dry but using the residual sweetness of the turbid mash I may push the fruit and bring it to the fore. With this in mind and using the grape ale I made as a guide I planned a recipe. Moderate alcohol and low bitterness at 17 IBU, with a little tartness from the fruit, some residual sweetness to let the seasonal plums come through but everything in balance.

I would have liked to use 3724 yeast as its generally better with a sourer siason and the plums would certainly add some acidity… but I didn’t have any so I used the traditional Belle Siason. It has a mixed reputation but I actually really like it. I did decide to temper it with a traditional Belgian ale yeast that is not too clovey – Mangrove Jacks M41. Both were co-pitched and allowed to ferment together.

Then I didn’t make the beer… and started with the fruit by making a wine. 3kg of plums were stoned and punched to mash them up. I didn’t add any pectic enzyme but you easily could. The reasoning behind it was that the beer is going to be hazy anyway and the fruit will ferment on its own and then also sit macerating in the beer fermentation to pull more flavour from the skins. I stirred in a campden tablet to kill any wild yeast and let it sit 24 hours to dissipate. Then I added the yeast and some nutrient. Three times a day I stirred the fruit so that it did not allow mold to grow on the surface. Knowing what wine yeast and beer yeast smells like it was a strange aroma of both as it fermented. Once the yeast was really starting to slow down I stopped the stirs and let it sit completely sealed to ferment further.

I made the beer using the petit turbid schedule below. It was labour intensive but good fun and I hit my marks on the step mashes really really well. I suspect that next time I will be frustrated as they will not be as spot on. I also had better efficiency than I expected and had a potential ABV of 4.4% rather than 4% and had a total of 24.5 litres of wort pulled rather than my traditional 22 litres that reduces down to 20 litres in the boil. The mash was cooled over 25 minutes rather than letting it cool ambiently overnight as a lambic beer does. Once in the fermenter the fruit was added, encased in a sparge bag to keep the skins together. There was no need to add yeast as it was with the fruit and no need to oxygenate as it was a huge colony that was still active. Half an hour later the yeast was fermenting very happily, after 12 hours it was absolutely roaring along so much that there were no visible bubbles from the blow off tube but a continuous stream like a hydrothermal vent.

Some people will no doubt think that I should have added the fruit after fermentation slowed down on the beer but I wanted to bottle quickly but maximise the fruit character with alcoholic maceration extracting flavour from the plum skins. Personally I think its a bit of a myth that flavour “boils off” with a strong fermentation. Others may not though. After 10 days I bottled the beer at 2.5 atmospheres. Two beers got a bit of yeast in them as the sparge bag settled in the fermenter but generally the highly floculating Belle and M41 yeast stayed nicely put at the bottom and the bag must have settled slowly rather than with a bump uplifting sediment.

This will definitely become my base for fruit beers from now on. There is more than a hint of plum and it is definitely deeper and more rounded that I have had in my bone dry saisons due to the slight subtle sweetness on the after taste. This sweetness from the starches left in the beer rounds off the fruit flavour rather than it just being one note of sourness and it can be drunk easily. The two yeasts means that the saison character is tempered as expected and allows the fruit to really come through with out much clove interfering. The final beer looks a little hazy but nothing crazy for an ale, colour is a a vibrant yellow orange from the fruit, not as dark or red as I was expecting though! The head is voluminous but disappears quickly but there’s a good refreshing fizz through out. I could add some oats for more head retention but I am very happy with this as it is. Next time I would love to do a blackcurrant, blackberry, elder and black, Jostaberry, gooseberry, greengage, apricot or maybe even strawberry version and I can choose to swap yeasts based on what I expect the acidity to be like, perhaps using 3724.

SAISON LATROBE: TURBID PLUM SAISON

- Batch: 20L (managed to pull 22litres)

- Start gravity: 1.044

- End gravity: yeah… Probably 1.10ish

- ABV: 6.5 final estimated. Was aiming for 4% from the malt but got 4.5%

- IBU: 17

- Colour: 3ish SRM and then the fruit.

Water profile: Tesco Ashbech pushed to a balanced ale

| Chemical | Target | |

| Calcium | Ca | 80 |

| Magnesium | Mg | 5 |

| Sodium | Na | 25 |

| Carbonate | CO3 | 15 |

| Sulphate | SO4 | 100 |

| Chloride | Cl | 75 |

OTHER FERMENTABLES!

| Fruit | Total | Per Gallon |

|---|---|---|

| Plums | 3kg | 750g |

- So you may want to add the plums after regular fermentation starts to slow but I chose to start the whole fermentation on the fruit. It left time to extract deeper flavour from the fruit skins. You could even ferment with a wine yeast and combine before bottling.

- I used Lalemand Belle Saison and Mangrove Jacks M41. Just go with whatever saison yeast you like.

- Stone the plums, punch them into squishiness. Add pectic enzyme if you wish and certainly a campden tablet to sanitise. Leave for 24 hours. Add your yeast then leave them to sit in a fermentation bucket for 12 days. Punch down the fruit cap at least once a day, preferably 3 or 4 times. Took 10 days to ferment almost through and I stopped pushing the cap down due to high alcohol and also a cance of oxidation. Once fermented pour the goo and skins into a sanitised sparge bag and add to the waiting fermenter.

GRAIN BILL

| Grain | Total | Percentage | Per Litre |

|---|---|---|---|

| German Pilsner | 3kg | 75.00% | 150g |

| Torrified Wheat | 1kg | 25.00% | 50g |

MASH

- Protein Rest – Start with all the grain and at a mash thickness of 1litre to 1kg of malt. Mashed at 45c for 10 minutes with a continuous good stir. (I slightly over shot and had 4.5 litres of water to 4kg of grain.)

- Gelatinization Rest – Add enough 75c water to get to 51c temperature in the mash. Hold for 10 minutes. I added 4 litres but anything between 1.8 to 2.5 l/kg is apparently acceptable.

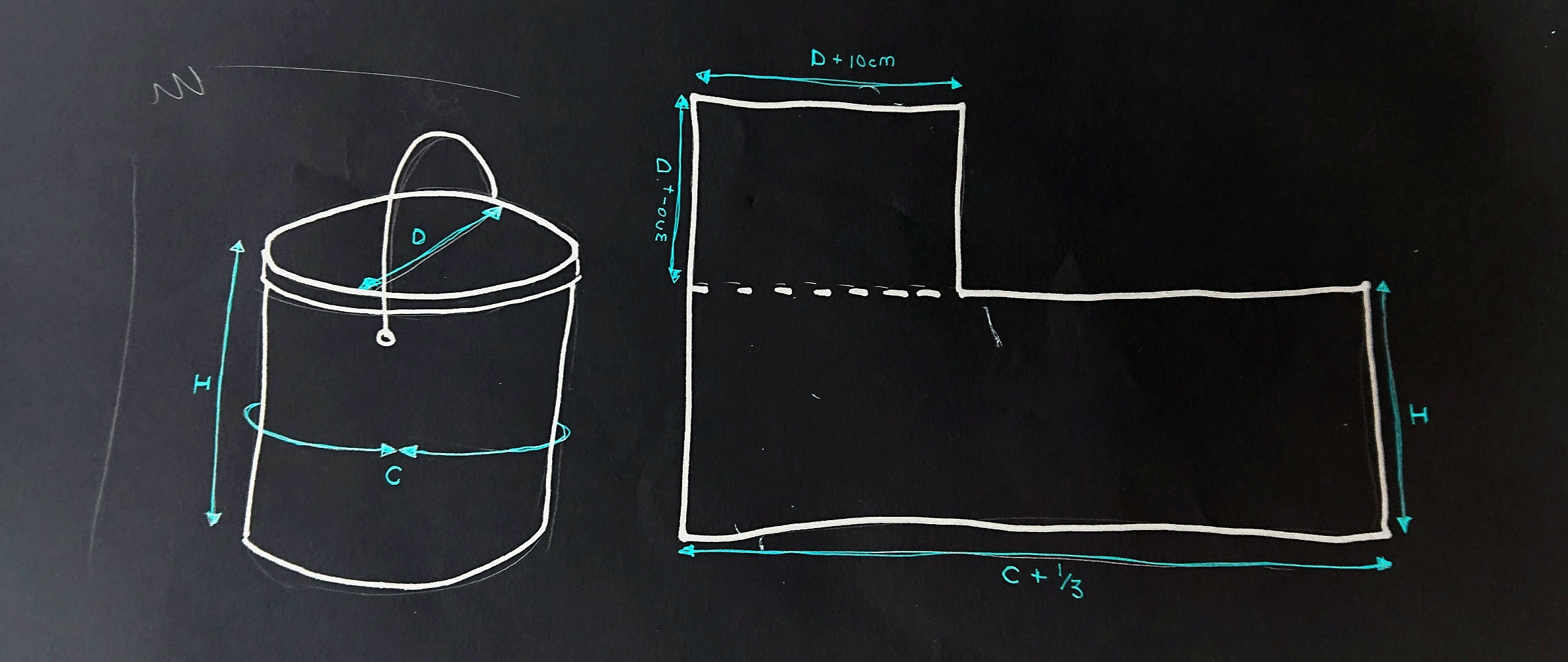

- Turbid pull – I pulled 3 litres of wort into a separate pan and heated to 74c for 20min then raised to a simmering boil for the rest of the mash schedule.

- Sacchrification Rest – Stir and add boiling water to get to 70c then rest for 60 minutes Add 250g rice hulls with 5 minutes to go to aid lautering

- Start to lauter the main mash.

- Reduce the turbid section to 70c with cold water and pour into the top of the wort so it can lauter though with the existing mash. Then sparge with 75c water to get the whole wort ready to boil. I did vorluf the first runnings.

- I collected about 24.5l and it entered the boil at 65c for a 90 min boil.

BOIL

| Hop | Alpha | Weight | Time | (Per Litre) |

| Herkules | 16.20% | 9g | 60min | 2.2g |

- Once chilled to 20c I poured over the plums. As it was active yeast I did not aerate. Started fermentation with no blow off for 24 hours then attached.

- Bottled after 12 days after the beer started to ferment and strongly carbonated at 2.5 atmospheres. Allowed to age for a month or longer and served cold from a fridge rather than cellar temperature.

SOURCES

http://www.horscategoriebrewing.com/2016/02/thoughts-on-johnson-1918-belgian.html